Research

- Home

- Research

Development of a flexible and adaptable spatial structural system

This research project builds upon a bottom-up design logic leading to an informed design strategy in the development of a reconfigurable non-standard structure. This may enable modularity and reconfigurable on the one side and optimized structural behavior as to time varying functional or environmental conditions on the other side. The suggested system consists of individual hinge-connected structural units geometrically defined as pairs of inclined equilateral triangles, that interact with each other and are controlled at local level through structural behavioral rules based on parametric physics-based simulation and kinetic analysis. Aim is to achieve design, construction and kinetic control of the proposed system, exhibiting at the same time self-organized behavior of its units. In general, the bottom-up strategies that evolve interaction behavior between individual entities and in turn the self-organized emerged results are correlated with the form-finding procedures for mass minimization, whereas individual particles under self-loading conditions are stabilized in space following the idea of hanging-chain technique.

Captions

1 – Self-rotation between individual units and overall behaviour

2 – Actuation case 1 and results obtained

3 – Actuation case 2 and results obtained

4 – Actuation case 3 and results obtained

5 – Actuation case 4 and results obtained

6 – Diagrams of four actuation scenarios

7 – System results of actuation case 3

8 – Structural analysis of the initial chain and the selected transformed chains

Internal Research Program, Department of Architecture, University of Cyprus

Research Team:

- O. Kontovourkis

- M.C. Phocas,

- E.G. Christoforou

- P. Konatzii

Publications

- Kontovourkis, O., Phocas, M.C., Christoforou, E. G., Konatzii, P., 2014. Informed design strategy for the development of a reconfigurable modular structure. In: M. Voyatzaki, ed. Proceedings of the ENHSA International Conference What’s the matter: Materiality and Materialism at the Age of Computation. Barcelona: COAC, ETSAB, ETSAV, pp. 753-767

- Kontovourkis, O., Phocas, M.C., Konatzii, P., 2015. Bottom-up design, construction and control of a reconfigurable structural system. Journal of the International Association of Shell and Spatial Structure: J.IASS, Vol. 56, No. 2, pp. 101-112

Kinetic formwork

This research investigation is concentrated on a robotic casting methodology for the development of complex ecological walls. The methodological framework includes digital design and physical robotic fabrication procedures, existing in a bidirectional manner where the design decision-making informs decisions taken during pre-construction stage and vice versa. In digital design stage, parametric design and multi-objective analysis procedures are introduced, aiming at finding the range of possible solutions under the influence of functional, environmental and structural design criteria. Functional design criterial include appropriate opening sizes and dimensions of walls, environmental design criterial include effective sun shading in the interior space as well as low environmental impact of solutions. Finally, structural criteria include appropriate dimensions and strength of construction materials. In the physical robotic fabrication stage the aim is to produce in actual scale optimum selected design results through the development and use of a kinetic formwork driven by robotic construction principles. The mechanism acts as an end effector tool that is mounted on an industrial robot, aiming to adapt its shape in different optimum design solutions offering flexibility during the robotic construction stage. The research puts forward the hypothesis that digital optimization procedures might be part of the construction decision-making process where architectural systems are examined in terms of their ability to be statically efficient and easily manufactured through the use of robotic and automation mechanisms.

Captions

1 – Conceptual framework of the proposed methodology

2 – Diagram of suggested methodology

3 – Sections of three representative brick geometries

4 – Section of the end-effector model

5 – Physical model of the custom-made end-effector tool mounted on the robotic arm

6 – Produced bricks in series

Ph.D Research, Department of Architecture, University of Cyprus

Research Team:

- O. Kontovourkis

- P. Konatzii

Publications

- Kontovourkis, O., Konatzii, P., 2016. Optimization Process Towards Robotic Manufacturing in Actual Scale – The Implementation of Genetic Algorithms in the Robotic Construction of Modular Formwork Systems. In A. Herneoja, T. Österlund and P. Markkanen, eds. Proceedings of the 34th Conference on Education in Computer Aided Architectural Design in Europe: Complexity & Simplicity (Volume 1). Oulu: University of Oulu, pp. 169-178 [link]

- Kontovourkis, O., Konatzii, P., 2018. Design-static analysis and environmental assessment investigation based on a kinetic formwork-driven by digital fabrication principles. Proceedings of the 6th eCAADe RIS Conference: Sustainable Computational Workflows,Computational Design and Fabrication towards Sustainable Products and Processes. Nicosia, University of Cyprus, pp.131-140 [link]

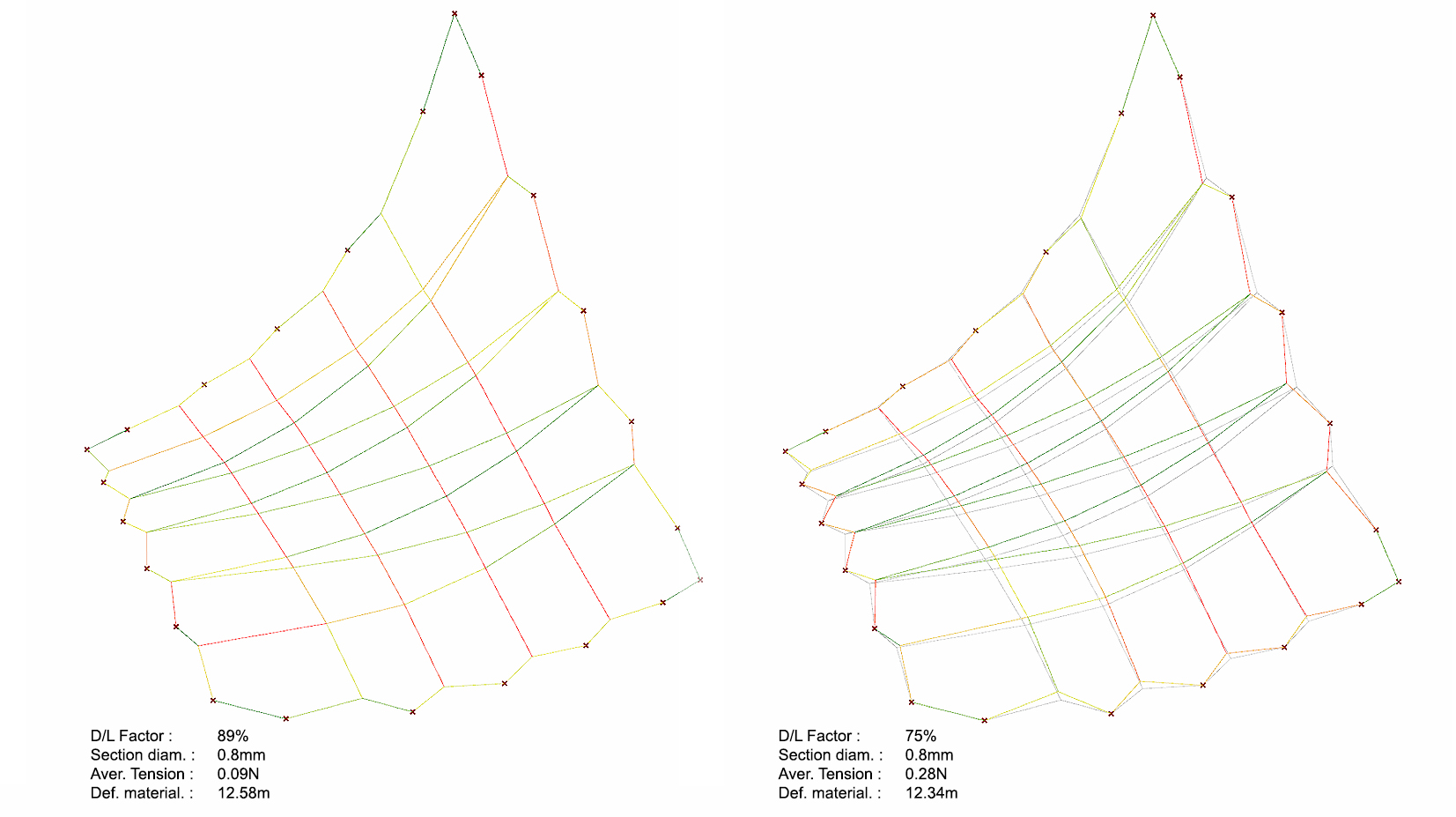

Clay Printing

The term Robotic Additive Manufacturing (RAM) is used to describe the three-dimensional robotic movement and material deposition in layers, leading to solidified products. Most commonly known as 3D printing, this technology has gained considerable attention the last few decades and today has succeeded to be a rapidly growing field worldwide with several technologies available for public use. Furthermore, recent developments in the area of computational design tools and their incorporation within a productive workflow that includes digital design and fabrication, open new direction in this area of research. All the above, open the possibility of applying RAM technologies in the construction industry, particularly towards the implementation of 3D printing processes in actual scale. An area under considerable attention is RAM with clay, which allows the manufacturing of complex and non-standard 3D morphologies in lower cost and more effectively but also considering the ecological aspect of the material evolved. In addition, RAM with clay overcome material limitations, opening new directions of implementation towards more sensible, flexible and versatile products based on a layer by layer material deposition approaches. This ongoing project builds on previous work done by d2AP , emphasizing on the installation of an industrial extruder for 3D clay printing (LDM Wasp Extruder) that is mounted on a robotic arm (ABB IRB 2600) and on toolpath planning in the parametric design environment of Grasshopper (plug-in for Rhino 3D) and robotic control software HAL for RAM execution of selected case studies using clay material mixtures. The process suggests an algorithm for system’s control as well as for robotic toolpath development applied in additive manufacturing of small to medium scale morphologies.

Research, Department of Architecture, University of Cyprus

Research Team:

- O. Kontovourkis

- G. Tryfonos

Publications

- Kontovourkis O. and Michael P., 2017. A robotically-driven additive construction planning process using an ecological material. The introduction of 3D clay printing for large scale construction. In Proceedings of the 5th eCAADe RIS, 95-104, Cardiff, UK.

- Kontovourkis, O. and Tryfonos, G., 2018. Integrating parametric design with robotic additive manufacturing for 3D clay printing: An experimental study. Proceedings of the 35th International Symposium on Automation and Robotics in Construction, Berlin, Germany [In Print].

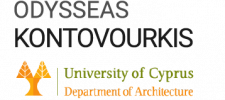

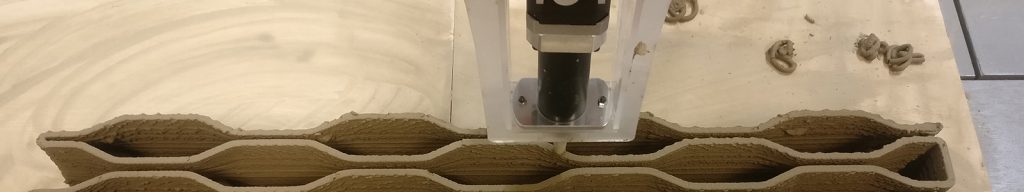

Tensile Robotics

This research presents an ongoing work towards the development of an integrated robotically-driven workflow that can be used for the design, development and subsequent fabrication of small-to large-scale elastic tensile mesh structures. This approach involves digital form-finding and optimization, driven by robotic manufacturing principles and it aims to overcome the limitations of currently available tools, to work either in the design or the fabrication phase of the process. At the same time, it involves the fabrication of systems in several scales followed by respective analyses of results according to the specific type and diameter of the material used. Specifically, form-finding and optimization are responsible for controlling the pretension of the elastic threads, aiming to determine the final tensile mesh and to generate the additive robotic tool-path. In parallel, the type and diameter of the material involved, define the necessary changes of the end-effector tool, which is responsible to implement the process. Despite that design results can be in any scale, for study purposes an experimentation into a small-scale is conducted, to evaluate the suggested automated construction process in general and the end-effector mechanism in particular.

Ph.D Research, Department of Architecture, University of Cyprus

Research Team:

- O. Kontovourkis

- G. Tryfonos

Publications

- Kontovourkis O., Tryfonos G., An integrated robotically-driven workflow for the development of elastic tensile structures in various scales. Sustainable Computational Workflows, 6th eCAADe Regional International Workshop Proceedings, Department of Architecture, University of Cyprus, Nicosia, Cyprus, 24-25 May 2018, pp. 111-120 [link]

- Kontovourkis, O. and Tryfonos, G., 2016. Design optimization and robotic fabrication of tensile mesh structures: The development and simulation of a custom-made end-effector tool. International Journal of Architectural Computing, SAGE, Vol. 14, No. 4, pp. 333-348

- Kontovourkis, O., Tryfonos, G., 2015. Robotic Fabrication of Tensile Mesh Structures and Real Time Response. The Development and Simulation of a Custom-Made End Effector Tool. Ιn: B. Martens, G. Wurzer, T. Grasl, W. E. Lorenz, R. Schaffranek, eds. Proceedings of the 33th Conference on Education in Computer Aided Architectural Design in Europe: Real Time – Extending the Reach of Computation (Volume 2). Wien: Technical University of Wien, pp. 389-398

Timber Robotics

This research attempts to reconsider the role of advanced tools and their effective implementation in the field of Architecture, Engineering and Construction (AEC) through the concept of sustainable construction. In parallel, the paper aims to discuss and find common ground for communication between industrial and experimental processes guided by sustainable criteria, an area of investigation that is currently in the forefront of the research work conducted in our robotic construction laboratory. Within this frame, an ongoing work into the design, analysis and automated construction of a timber structure in actual scale is exemplified and used as a pilot study for further discussion. Specifically, the structure consists of superimposed layers of timber elements that are robotically cut and assembled together, formulating the overall structural system. In order to achieve a robust, reliable and economically feasible solution and to control the automated construction process, a multi-objective design optimization process using evolutionary principles is applied. Our purpose is to investigate possibilities for sustainable construction considering minimization of cost and material waste, and in parallel, discussing issues related to the environmental impact and the feasibility of solutions to be realized in actual scale.

Research, Department of Architecture, University of Cyprus

Research Team:

- O. Kontovourkis

- G. Tryfonos

- P. Konatzii

- S. Christofi

- C. Katsambas

- S. Stylianou

Publications

- Kontovourkis, O., 2017. Multi-objective design optimization and robotic fabrication towards sustainable construction – The example of a timber structure in actual scale. In A. Fioravanti, S. Cursi, S. Elahmar, S. Gargaro, G. Loffreda, G. Novembri, A. Trento, eds. Proceedings of the 35th Conference on Education in Computer Aided Architectural Design in Europe: ShoCK! – Sharing Computational Knowledge! (Volume 2). Rome: Sapienza University of Rome, pp. 125-134